Sie haben Fragen – wir freuen uns darauf von Ihnen zu hören!

The HAWEMAT 3000 Granite is the first full mineral compound base concept with integrated cabin in the field of grinding technology.

Due to new cab design, the access to the machine is much larger through the double door opening, thus increasing the overall ease of operation.

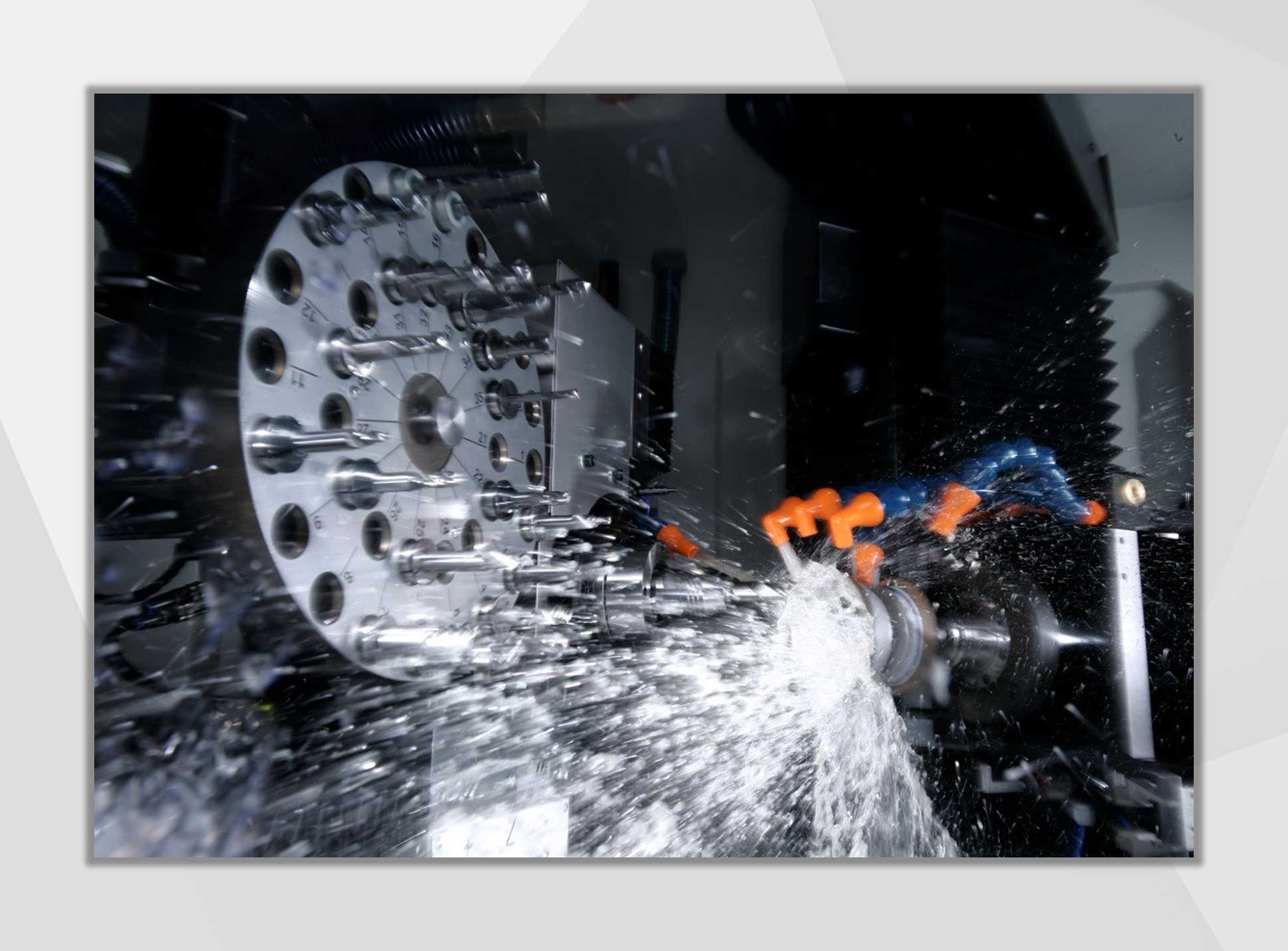

The compact mineral casting body is reinforced by granite elements in the axes X, Y and B. This ensures a low thermal expansion and high rigidity of the whole machine system. This basis offers a wide range of applications, especially for the production of high-precision tools. The production of small to large tools in connection with different loading systems offers highest efficiency.

Automatic grinding wheel changer with 6 places (option)

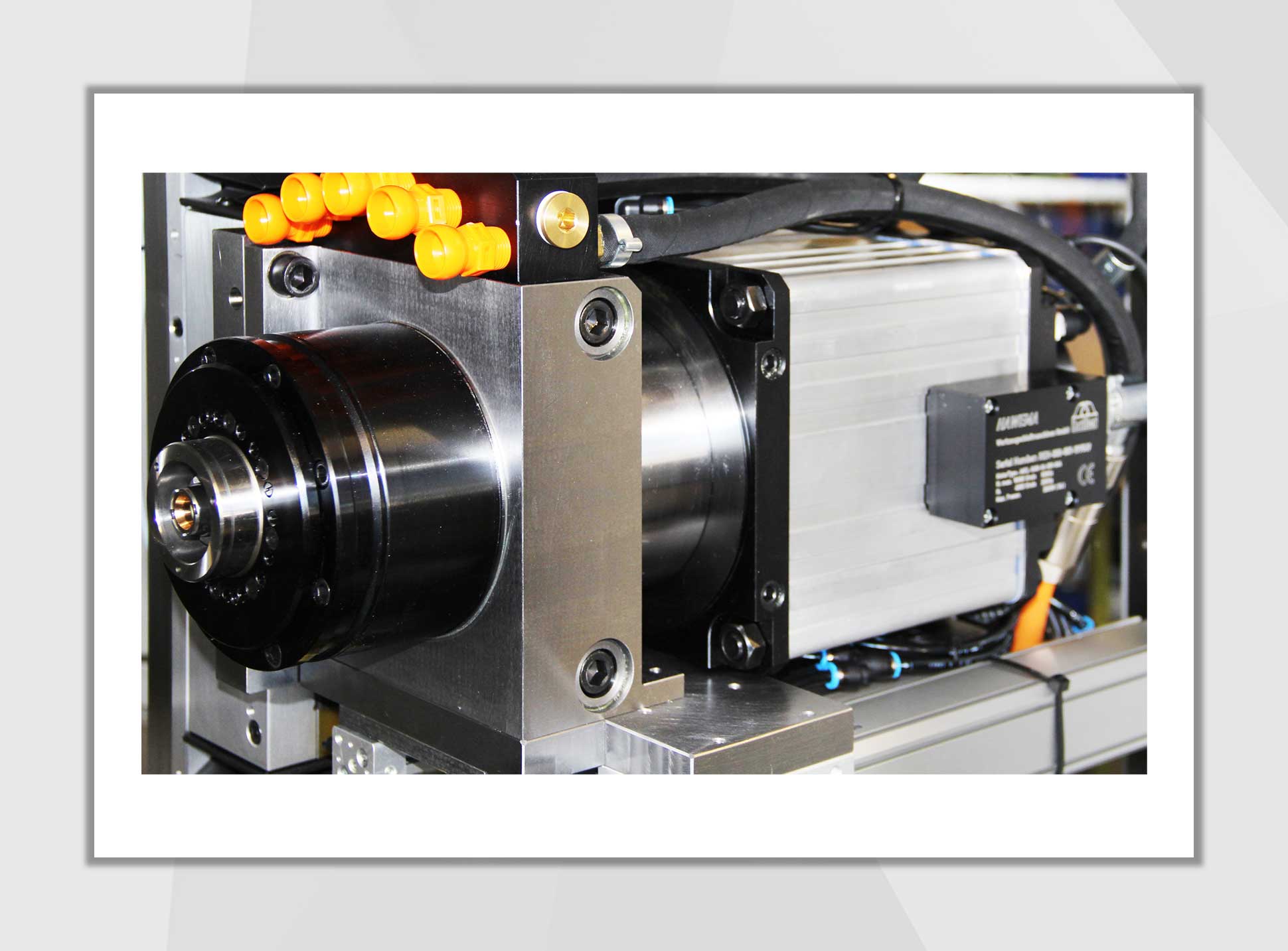

High precision grinding spindle, 20 kW/S6 direct drive

Pick-up loading system ILS 35

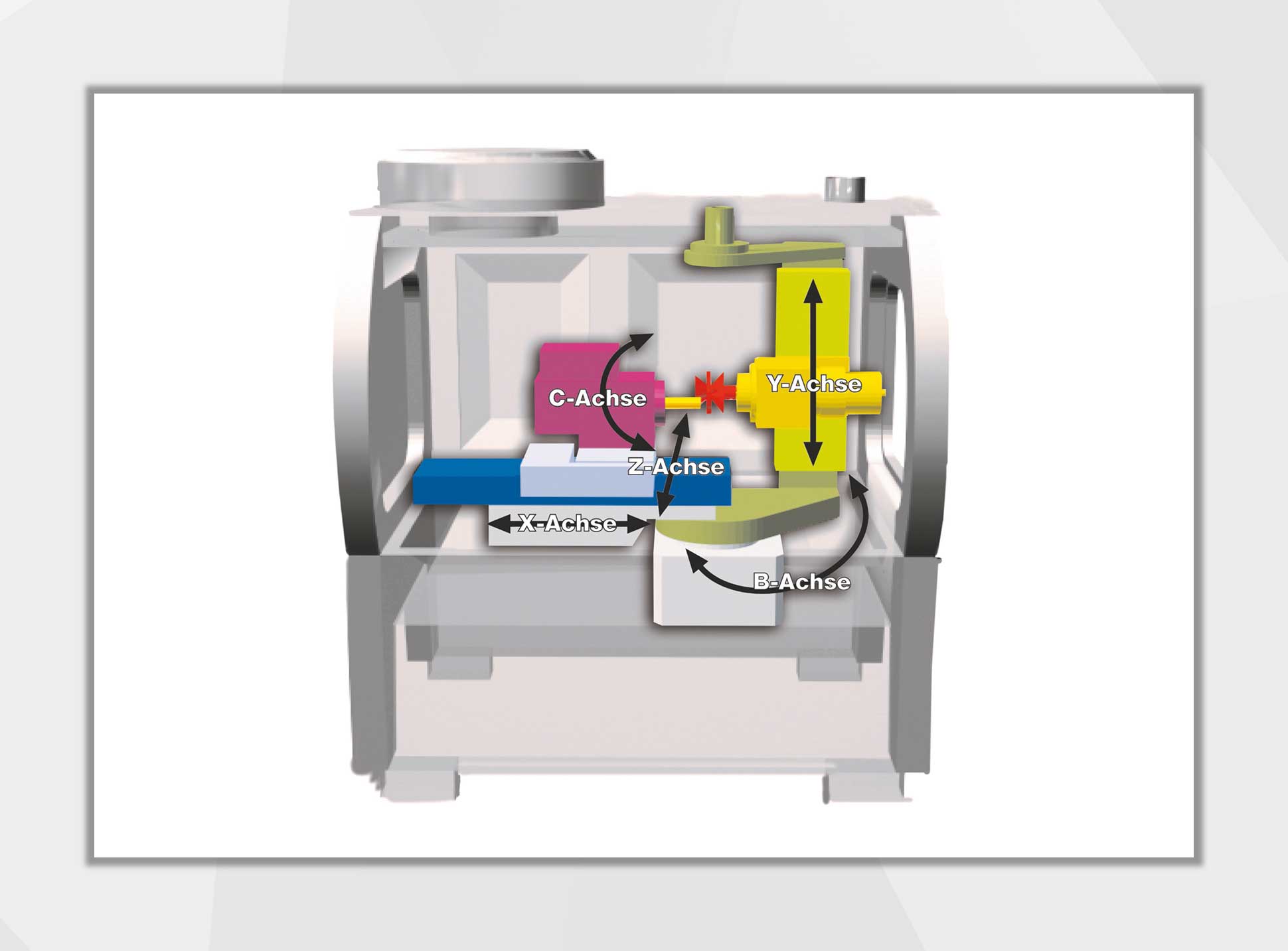

The principle

The ideal positioning of the 5 axes to each other allows:

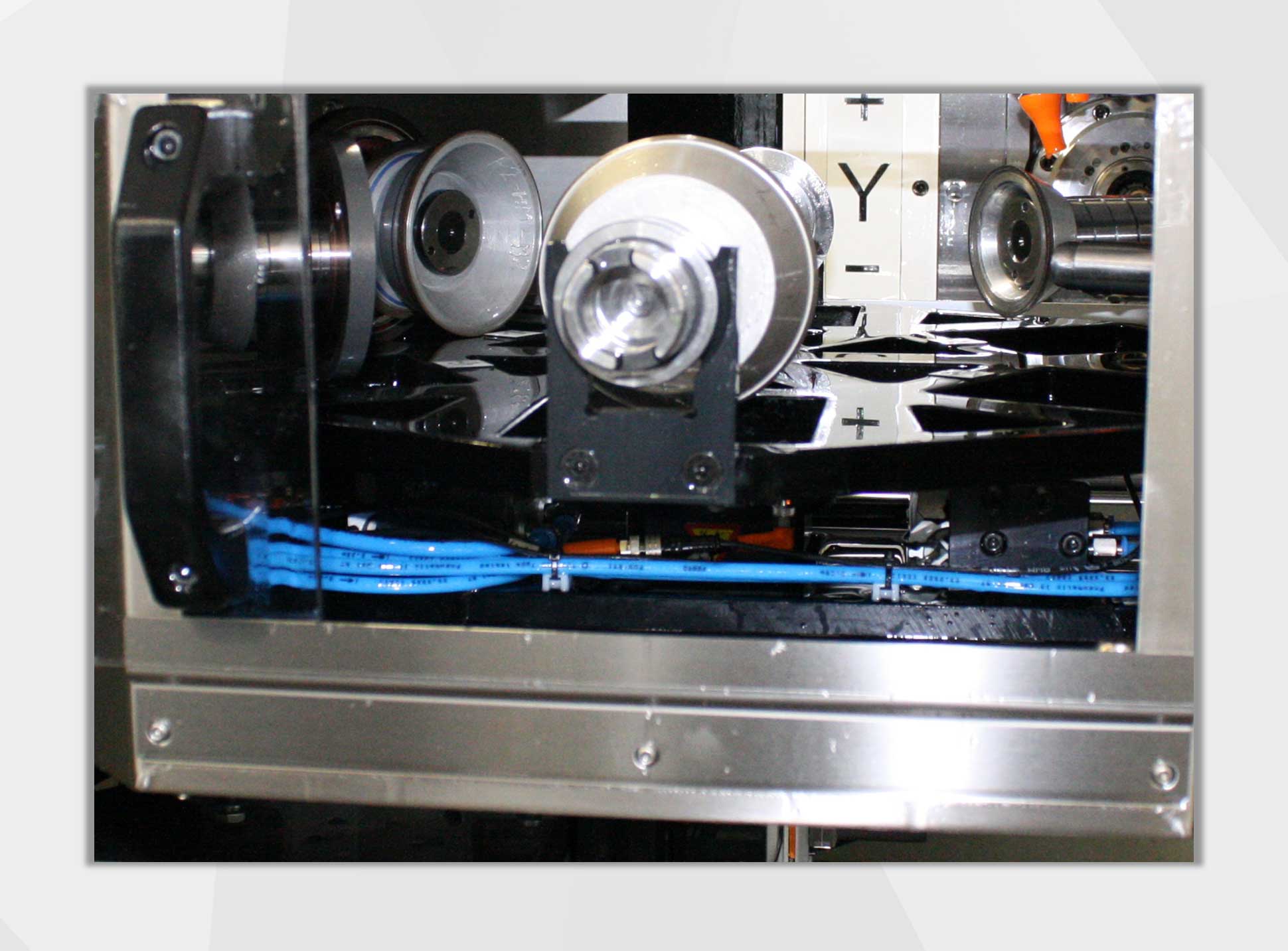

The advantage of the double-bearing grinding column is the high rigidity in the entire system, which in turn brings very high precision.

Complete machining max. workpiece lenght

300 mm

Complete machining max. diameter

150 mm

Tool measurement

3D-Messtaster Marposs

Grinding wheels or grinding wheel package

3D-Messtaster Marposs

14,5 kW / S6 oil cooled

0-10000 rpm

Max. diameter

125 mm

Grinding wheels per holder

1-4 wheels

Cooling with cooling valve

Program-controlled

3 valves

3-package wheel changer

HSK 50 for wheel max. 125 mm Ø

Optional 6-package wheel changer

HSK 50 for wheel max. 125 mm Ø

Standard

Spindle taper

SK 50

Clamping system

mechanical / manual

Option

Clamping system

pneumatic/automatic

Optional indexing head ISO 50

Direct drive

Torque motor 1000 rpm

B-axis (pivot axis)

backlash-free HarmonicDrive system

Option

Direct drive (torque motor with brake)

CNC control unit

NUM-Flexium+

TFT colour monitor

19 inch

NUMROTOplus milling cutters, drills, special tools, 3-D simulation, 3-D collision monitoring

external

Cartridge filter system

manual cleaning

HAWEMA OC 12

Cartridge filter system

automatic cleaning

HAWEMA OC 20

Oil mist exhaust unit

Ø 150 mm

Longitudinal

X-axis

350 mm – optional 420 mm

Lateral

Z-axis

230 mm

Vertikal

Y-axis

350 mm

Resolution

X-Y-Z-axis 0,0003 mm resp. 0,0001 mm

Speed

X-Y-Z-axis 15 m/ min. rotational movement

Rotation

C-axis

360°

Resolution

C-axis

0,0001 mm

Speed

C-axis

1000 rpm

Axis of rotation

B-axis

195°

Speed

B-axis

112°/sec.

Axis drives

high-output AC servo motors | NUM-servo motors

Height |width | depth

2200 | 3000 | 2000 mm

Weight

approx. 5000 kg

Power supply

3 x 400 V – 50/60 Hz

Power input

27 kW

Air supply

6-8 bar

Colour

RAL 7035 light grey

Height |width | depth

2400 | 4000 | 3000 mm